- Introduction to laser cleaning technology

- Types of contaminants on glass surfaces

- Environmental impact of laser cleaning

- Case studies of successful laser cleaning projects

- Maintenance requirements for laser cleaning equipment

- Role of laser parameters in achieving optimal cleaning results

- Role of laser cleaning in the aerospace industry for glass components

- Effectiveness of laser cleaning on removing hard water stains from glass

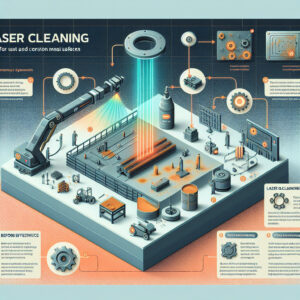

Introduction to laser cleaning technology

How does laser cleaning work?

Laser cleaning works by directing a high-energy laser beam onto the surface of the material to be cleaned. The intense heat generated by the laser vaporizes the contaminants, leaving behind a clean surface. This process is non-abrasive and does not damage the underlying material, making it ideal for delicate surfaces.

Benefits of laser cleaning technology

- Environmentally friendly – Laser cleaning does not require the use of chemicals or solvents, making it an eco-friendly cleaning solution.

- Efficient – Laser cleaning is a fast and efficient method that can remove contaminants quickly and effectively.

- Precision – Laser cleaning allows for precise control over the cleaning process, ensuring that only the desired material is removed.

- Versatile – Laser cleaning can be used on a wide range of materials, including metals, plastics, ceramics, and more.

Applications of laser cleaning technology

Laser cleaning technology is used in a variety of industries, including manufacturing, automotive, aerospace, and more. It can be used to clean surfaces prior to painting, welding, or bonding, as well as for restoration and conservation purposes.

Conclusion

Laser cleaning technology offers a modern and efficient solution for removing contaminants from surfaces. Its precision, efficiency, and versatility make it a valuable tool for a wide range of applications.

#laser #cleaning #technology #innovative #efficient #precise #environmentallyfriendly #versatile #manufacturing #automotive #aerospace #restoration #conservation

frazy kluczowe:

– cutting-edge method used to remove contaminants

– non-abrasive and does not damage the underlying material

– fast and efficient method that can remove contaminants quickly and effectively

Types of contaminants on glass surfaces

– Dust and dirt particles are some of the most common contaminants found on glass surfaces. They can accumulate over time, making the glass appear dirty and dull.

2. Fingerprints

– Fingerprints are another common type of contaminant that can be found on glass surfaces, especially on windows and mirrors. They can be unsightly and difficult to remove.

3. Water spots

– Water spots are caused by mineral deposits left behind when water evaporates on the glass surface. They can be particularly stubborn to remove and can make the glass appear cloudy.

4. Grease and oil

– Grease and oil can be transferred onto glass surfaces from hands or cooking activities. They can leave behind a sticky residue that attracts dust and dirt.

5. Hard water stains

– Hard water stains are caused by mineral deposits from water that contains high levels of calcium and magnesium. They can be difficult to remove and can make the glass appear cloudy and streaky.

6. Mold and mildew

– Mold and mildew can grow on glass surfaces in damp and humid environments. They can be harmful to health and can cause discoloration and damage to the glass.

Proper cleaning and maintenance of glass surfaces is essential to prevent the buildup of contaminants and keep them looking clean and clear. Using the right cleaning products and techniques can help to effectively remove these contaminants and restore the glass to its original condition.

#contaminants #glasssurfaces #cleaning #maintenance #dust #fingerprints #waterspots #grease #oil #hardwaterstains #mold #mildew

frazy kluczowe:

– How to remove water spots from glass surfaces

– Best cleaning products for glass surfaces

– Preventing mold and mildew on glass surfaces

– Tips for maintaining clean windows and mirrors

Environmental impact of laser cleaning

Energy consumption

One of the main environmental concerns associated with laser cleaning is the energy consumption. Laser cleaning requires a significant amount of energy to operate, which can contribute to greenhouse gas emissions and other environmental impacts. It is important for companies using laser cleaning technology to consider ways to reduce energy consumption and increase efficiency.

Waste generation

Another environmental impact of laser cleaning is the generation of waste. The process can produce hazardous waste materials, such as metal particles and chemical residues, that need to be properly disposed of to prevent environmental contamination. Companies should implement proper waste management practices to minimize the impact of laser cleaning on the environment.

Chemical usage

Some laser cleaning processes require the use of chemicals to enhance the cleaning efficiency. These chemicals can be harmful to the environment if not properly handled and disposed of. Companies should use environmentally friendly chemicals and follow proper safety protocols to minimize the environmental impact of chemical usage in laser cleaning.

Water consumption

Water is often used in laser cleaning processes to help remove contaminants from surfaces. However, excessive water consumption can strain local water resources and contribute to water pollution. Companies should implement water recycling and conservation measures to reduce the environmental impact of laser cleaning on water resources.

Noise pollution

Laser cleaning can also contribute to noise pollution, especially in industrial settings where multiple lasers are operating simultaneously. Excessive noise can have negative impacts on wildlife and human health. Companies should implement noise reduction measures to minimize the environmental impact of laser cleaning on noise pollution.

Conclusion

Overall, laser cleaning is a valuable technology for removing contaminants from surfaces efficiently. However, it is important for companies to consider the environmental implications of laser cleaning and take steps to minimize its impact on the environment. By reducing energy consumption, managing waste properly, using environmentally friendly chemicals, conserving water, and reducing noise pollution, companies can ensure that laser cleaning remains a sustainable and environmentally friendly technology.

- energy consumption

- waste generation

- chemical usage

- water consumption

- noise pollution

- greenhouse gas emissions

- hazardous waste materials

- environmentally friendly chemicals

- water recycling

- noise reduction measures

#environment #laser #cleaning #energyconsumption #wastegeneration #chemicalusage #waterconsumption #noisepollution #greenhousegases #hazardouswaste #recycling #sustainability #environmentallyfriendlychemicals #pollutioncontrol #noisecontrol

Case studies of successful laser cleaning projects

Automotive industry

One of the most common applications of laser cleaning in the automotive industry is the removal of paint and rust from metal surfaces. A recent project involved the cleaning of car body panels before painting, resulting in a significant reduction in processing time and improved paint adhesion. The use of laser cleaning also eliminated the need for harsh chemicals, making it a more sustainable option for car manufacturers.

Aerospace industry

In the aerospace industry, laser cleaning has been used to remove oxidation and corrosion from aircraft components. A case study conducted by a major aircraft manufacturer showed that laser cleaning was able to restore the surface finish of critical parts, extending their lifespan and reducing maintenance costs. The precision and control offered by laser cleaning technology made it an ideal solution for delicate aerospace applications.

Historical preservation

Laser cleaning has also been employed in the field of historical preservation to remove dirt and grime from ancient artifacts and monuments. A project carried out at a museum involved the cleaning of a marble statue dating back to the Roman era, revealing intricate details that had been obscured by years of dirt and pollution. The non-invasive nature of laser cleaning ensured that the statue was not damaged during the cleaning process, preserving it for future generations to enjoy.

Conclusion

These case studies demonstrate the versatility and effectiveness of laser cleaning technology in a variety of industries. From automotive to aerospace to historical preservation, laser cleaning has proven to be a valuable tool for removing contaminants and restoring surfaces to their original condition. As technology continues to advance, we can expect to see even more innovative applications of laser cleaning in the future.

- Efficiency

- Sustainability

- Precision

- Non-invasive

- Automotive industry

- Aerospace industry

- Historical preservation

#laser #cleaning #projects #success #technology

Maintenance requirements for laser cleaning equipment

- Regular cleaning: It may seem counterintuitive, but laser cleaning equipment itself needs to be cleaned regularly. Dust and debris can accumulate on the lenses and mirrors, affecting the quality of the laser beam. Use a soft, lint-free cloth to gently wipe down the equipment after each use.

- Calibration: Laser cleaning equipment should be calibrated periodically to ensure that it is operating at peak efficiency. This may involve adjusting the power settings, beam focus, or other parameters to maintain consistent performance.

- Inspecting for damage: Check the equipment regularly for any signs of damage or wear. This includes checking the cables, connectors, and other components for fraying, corrosion, or other issues that could affect performance.

- Replacing consumable parts: Some parts of laser cleaning equipment, such as lenses or filters, may need to be replaced periodically. Keep track of the manufacturer’s recommendations for replacement intervals and be sure to use high-quality, compatible parts.

- Proper storage: When not in use, laser cleaning equipment should be stored in a clean, dry environment to prevent damage from moisture, dust, or other contaminants. Follow the manufacturer’s guidelines for storage and transportation to ensure the equipment remains in good condition.

By following these maintenance requirements, you can help ensure that your laser cleaning equipment continues to perform effectively and efficiently for years to come.

#laser #cleaning #equipment #maintenance #requirements #calibration #inspection #replacement #parts #storage

frazy kluczowe:

– Maintenance requirements for laser cleaning equipment

– Laser cleaning equipment maintenance tips

– How to maintain laser cleaning equipment

– Importance of regular maintenance for laser cleaning equipment

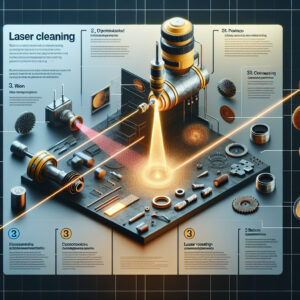

Role of laser parameters in achieving optimal cleaning results

Laser Parameters

There are several key parameters that must be considered when using lasers for cleaning purposes. These include:

| Parameter | Description |

|---|---|

| Wavelength | The wavelength of the laser determines its interaction with different materials. Shorter wavelengths are more effective for removing organic contaminants, while longer wavelengths are better for inorganic materials. |

| Pulse Duration | The duration of each laser pulse affects the amount of energy delivered to the surface. Shorter pulses are better for delicate materials, while longer pulses are more effective for stubborn contaminants. |

| Power Density | The power density of the laser beam determines the intensity of the cleaning process. Higher power densities can remove contaminants more quickly, but may also damage the surface if not controlled properly. |

| Spot Size | The size of the laser spot on the surface affects the area that can be cleaned in a single pass. Smaller spots are more precise, while larger spots cover more surface area but may be less effective at removing contaminants. |

Optimizing Laser Parameters

To achieve optimal cleaning results, it is important to carefully adjust these parameters based on the specific requirements of the cleaning task. For example, when cleaning delicate materials, a shorter wavelength and pulse duration may be necessary to avoid damage. On the other hand, when dealing with stubborn contaminants, a higher power density and larger spot size may be more effective.

It is also important to consider the type of contaminant being removed, as different materials may require different laser parameters for optimal cleaning. By carefully controlling these parameters, it is possible to achieve efficient and effective cleaning results on a wide range of surfaces.

Conclusion

In conclusion, the role of laser parameters in achieving optimal cleaning results cannot be overstated. By carefully adjusting parameters such as wavelength, pulse duration, power density, and spot size, it is possible to maximize cleaning efficiency and achieve superior results. With the right combination of parameters, laser cleaning can be a highly effective method for removing contaminants from surfaces of all types.

#laser #cleaning #parameters #wavelength #pulse duration #power density #spot size #contaminants #surface #efficiency

frazy kluczowe:

– achieving optimal cleaning results

– laser parameters for cleaning efficiency

– controlling laser parameters for effective cleaning

– maximizing cleaning results with laser technology

Role of laser cleaning in the aerospace industry for glass components

- Precision: Laser cleaning allows for precise removal of contaminants without damaging the underlying glass surface.

- Efficiency: Laser cleaning is a fast and efficient process, reducing downtime and increasing productivity.

- Safety: Laser cleaning eliminates the need for harsh chemicals and abrasive materials, making it a safer option for workers and the environment.

- Cost-effective: While the initial investment in laser cleaning technology may be high, the long-term cost savings make it a cost-effective solution for aerospace companies.

Overall, laser cleaning plays a crucial role in ensuring the reliability and performance of glass components in the aerospace industry. Its ability to remove contaminants with precision and efficiency makes it an invaluable tool for maintaining the high standards of cleanliness required in aerospace applications.

Keywords: laser cleaning, aerospace industry, glass components, precision, efficiency, safety, cost-effective

Long-tail phrases: role of laser cleaning in aerospace, benefits of laser cleaning, laser cleaning technology in glass components

#laser #cleaning #aerospace #glass #components #precision #efficiency #safety #costeffective

role of laser cleaning in aerospace, benefits of laser cleaning, laser cleaning technology in glass components

Effectiveness of laser cleaning on removing hard water stains from glass

How does laser cleaning work?

Laser cleaning uses a high-energy laser beam to vaporize contaminants on the surface of the glass. The intense heat generated by the laser breaks down the mineral deposits, allowing them to be easily wiped away. This process is non-abrasive and does not damage the glass surface, making it an ideal method for removing hard water stains.

Benefits of laser cleaning

There are several benefits to using laser cleaning for removing hard water stains from glass:

| Benefit | Description |

|---|---|

| Efficiency | Laser cleaning is a fast and effective method for removing hard water stains. |

| Gentleness | The non-abrasive nature of laser cleaning ensures that the glass surface is not damaged during the cleaning process. |

| Precision | Laser cleaning can target specific areas of the glass surface, ensuring thorough removal of hard water stains. |

Conclusion

Laser cleaning is a highly effective method for removing hard water stains from glass surfaces. Its efficiency, gentleness, and precision make it a superior alternative to traditional cleaning methods. By using laser cleaning, you can restore the beauty of your glass surfaces without the risk of damage.

#laser #cleaning #hardwaterstains #glass #efficiency #gentleness #precision #nonabrasive

słowa kluczowe: laser cleaning, hard water stains, glass, efficiency, gentleness, precision, non-abrasive

frazy kluczowe: laser cleaning for hard water stains removal, gentle and efficient glass cleaning, precision laser cleaning method.

- Laser cleaning for removing rust and corrosion from metal surfaces - 13 August 2024

- What is IT consulting? - 7 May 2024

- Laser cleaning for removing contaminants from glass surfaces - 22 February 2024