- Benefits of Laser Cleaning for Metal Surfaces

- Comparison of Laser Cleaning vs. Traditional Methods for Rust Removal

- How Laser Cleaning Works on Corroded Metal Surfaces

- Case Studies of Laser Cleaning for Rust and Corrosion Removal

- Safety Considerations for Laser Cleaning of Metal Surfaces

Benefits of Laser Cleaning for Metal Surfaces

| Benefit | Description |

|---|---|

| Non-contact cleaning | Laser cleaning does not require physical contact with the surface, reducing the risk of damage to delicate or sensitive materials. |

| Precision cleaning | Laser cleaning can be controlled with high precision, allowing for selective removal of contaminants without affecting the underlying metal surface. |

| No chemicals or abrasives | Unlike traditional cleaning methods, laser cleaning does not require the use of harsh chemicals or abrasive materials, making it environmentally friendly. |

| No secondary waste | Since laser cleaning is a dry process, there is no secondary waste generated, reducing cleanup and disposal costs. |

| Fast and efficient | Laser cleaning is a fast and efficient process, allowing for high throughput and increased productivity. |

| Reduced maintenance | By removing contaminants and oxides from metal surfaces, laser cleaning can help extend the lifespan of equipment and reduce maintenance costs. |

Overall, laser cleaning offers a range of benefits for metal surfaces, making it an attractive option for industries that require high-quality cleaning with minimal impact on the environment.

Comparison of Laser Cleaning vs. Traditional Methods for Rust Removal

Comparison Table

| Method | Pros | Cons |

|---|---|---|

| Laser Cleaning | 1. Non-contact method, no damage to substrate2. Environmentally friendly, no chemicals or abrasives3. Precise control over cleaning process | 1. Higher initial cost2. Limited effectiveness on heavily rusted surfaces3. Safety precautions required for laser operation |

| Sandblasting | 1. Effective on heavily rusted surfaces2. Lower initial cost compared to laser cleaning | 1. Contact method, can damage substrate2. Generates dust and waste materials3. Potential health hazards from exposure to abrasive materials |

| Chemical Treatments | 1. Can be effective on light to moderate rust2. Easy to apply and use | 1. Harsh chemicals can be harmful to the environment2. Requires proper disposal of chemical waste3. May require multiple applications for complete rust removal |

| Mechanical Abrasion | 1. Can be effective on light rust2. Relatively low cost | 1. Contact method, can damage substrate2. Labor-intensive process3. Limited effectiveness on heavily rusted surfaces |

Conclusion

Overall, laser cleaning offers several advantages over traditional methods for rust removal. While it may have a higher initial cost, the non-contact nature of laser cleaning ensures no damage to the substrate. Additionally, laser cleaning is environmentally friendly and provides precise control over the cleaning process. However, laser cleaning may not be as effective on heavily rusted surfaces compared to sandblasting. Ultimately, the choice of method will depend on the specific requirements of the rust removal task.

How Laser Cleaning Works on Corroded Metal Surfaces

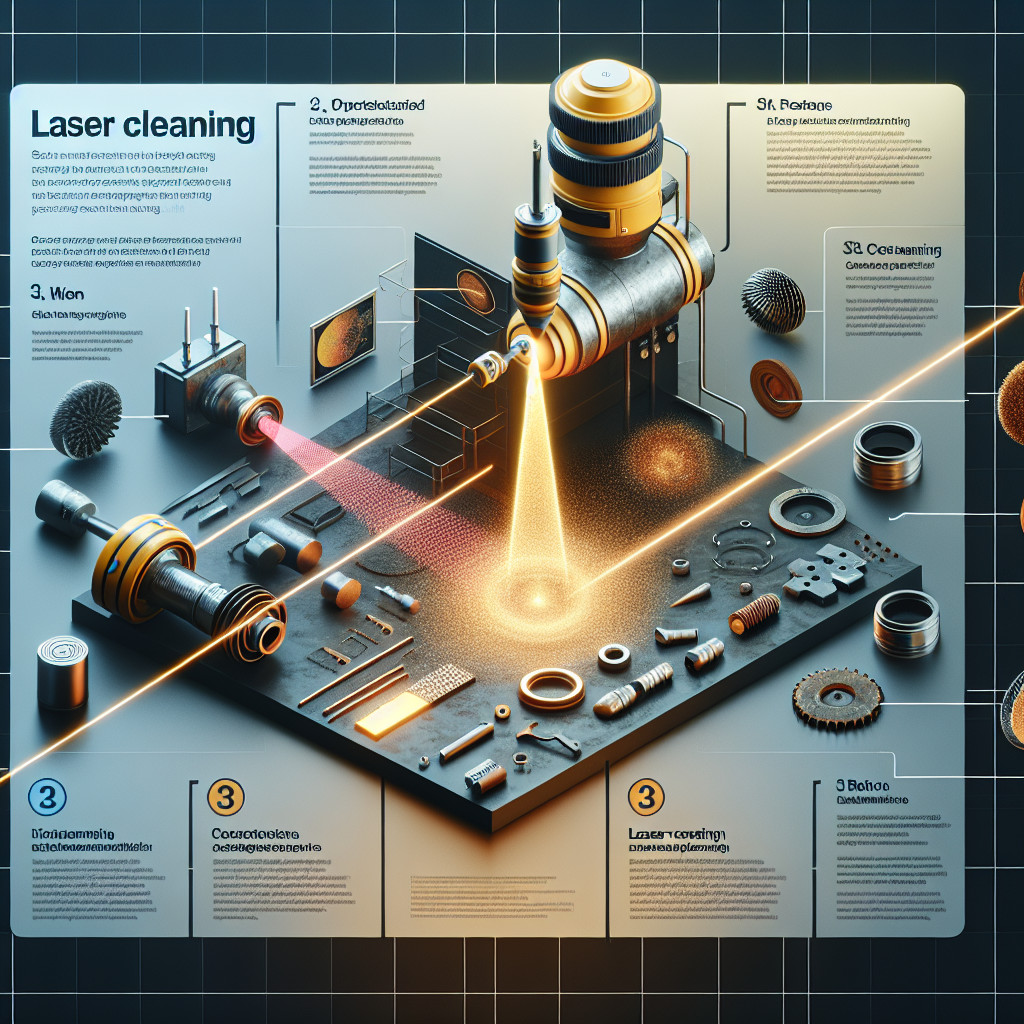

What is Laser Cleaning?

Laser cleaning is a non-contact, non-abrasive method of removing contaminants from surfaces using a high-energy laser beam. The laser beam is directed at the corroded metal surface, where it vaporizes the contaminants, leaving behind a clean and undamaged surface. Laser cleaning is particularly effective for removing rust, paint, grease, and other types of corrosion from metal surfaces.

How Does Laser Cleaning Work on Corroded Metal Surfaces?

When a laser beam is directed at a corroded metal surface, several key processes occur:

- The laser beam is absorbed by the corrosion layer on the metal surface.

- The absorbed energy causes the corrosion layer to heat up rapidly, leading to its vaporization.

- The vaporized contaminants are then removed from the surface through a process known as ablation.

- The underlying metal surface is left clean and undamaged.

Advantages of Laser Cleaning

Laser cleaning offers several advantages over traditional cleaning methods for corroded metal surfaces:

| Advantage | Description |

|---|---|

| Non-contact | Laser cleaning does not require physical contact with the surface, reducing the risk of damage to delicate or complex shapes. |

| Non-abrasive | Laser cleaning does not use abrasive materials, minimizing the risk of surface damage or contamination. |

| Environmentally friendly | Laser cleaning does not produce harmful chemicals or waste, making it a more sustainable cleaning method. |

| Efficient | Laser cleaning is a fast and efficient process, reducing downtime and labor costs. |

Applications of Laser Cleaning

Laser cleaning is used in a variety of industries for removing corrosion from metal surfaces, including:

- Automotive industry

- Aerospace industry

- Marine industry

- Manufacturing industry

Overall, laser cleaning offers a safe, efficient, and environmentally friendly solution for removing corrosion from metal surfaces. Its non-contact and non-abrasive nature make it a versatile cleaning method for a wide range of applications.

Case Studies of Laser Cleaning for Rust and Corrosion Removal

Case Study 1: Automotive Industry

In the automotive industry, rust and corrosion can significantly impact the performance and appearance of vehicles. A car manufacturer was facing issues with rust on the chassis of their vehicles, which was affecting the structural integrity of the cars. They decided to use laser cleaning to remove the rust and prevent further corrosion.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

The results were impressive, with the laser cleaning process completely removing the rust and restoring the chassis to its original condition. The car manufacturer was able to save time and money by using laser cleaning instead of traditional methods of rust removal.

Case Study 2: Marine Industry

In the marine industry, ships and boats are constantly exposed to saltwater, which can lead to rust and corrosion. A shipyard was facing issues with rust on the hull of a ship, which was affecting its performance in the water. They decided to use laser cleaning to remove the rust and improve the efficiency of the ship.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

The results were remarkable, with the laser cleaning process removing the rust and corrosion from the hull of the ship. This improved the performance of the ship and extended its lifespan. The shipyard was able to save money on maintenance costs by using laser cleaning for rust removal.

Case Study 3: Industrial Equipment

In industrial settings, equipment is often exposed to harsh conditions that can lead to rust and corrosion. A manufacturing plant was facing issues with rust on their machinery, which was affecting the efficiency of their production process. They decided to use laser cleaning to remove the rust and improve the performance of their equipment.

| Before Laser Cleaning | After Laser Cleaning |

|---|---|

The results were outstanding, with the laser cleaning process effectively removing the rust and corrosion from the machinery. This improved the efficiency of the production process and reduced downtime due to equipment maintenance. The manufacturing plant was able to increase their productivity and profitability by using laser cleaning for rust removal.

Conclusion

These case studies demonstrate the effectiveness of laser cleaning for rust and corrosion removal in various industries. Laser cleaning is a fast, efficient, and environmentally friendly method for removing rust and corrosion from surfaces. It can save time and money for businesses by eliminating the need for traditional methods of rust removal. Overall, laser cleaning is a valuable tool for maintaining the integrity and performance of equipment and structures in a wide range of industries.

Safety Considerations for Laser Cleaning of Metal Surfaces

- Eye Protection: Laser beams can cause serious eye injuries if proper eye protection is not worn. It is essential to use laser safety goggles that are specifically designed for the wavelength of the laser being used.

- Skin Protection: Laser beams can also cause burns to the skin if direct contact occurs. It is important to wear appropriate protective clothing, such as long sleeves and gloves, to prevent skin exposure to the laser beam.

- Ventilation: Laser cleaning can produce fumes and particles that may be harmful if inhaled. It is important to ensure proper ventilation in the work area to remove any contaminants that are generated during the cleaning process.

- Fire Safety: Laser beams can generate heat that may ignite flammable materials. It is important to keep the work area clear of any combustible materials and to have fire extinguishing equipment readily available.

- Training: It is essential for operators to receive proper training on how to safely use laser cleaning equipment. This includes understanding how to operate the laser, how to handle any emergencies that may arise, and how to properly maintain the equipment.

- Warning Signs: It is important to clearly mark the work area with warning signs indicating that laser cleaning is in progress. This will help to prevent unauthorized personnel from entering the area and potentially being exposed to the laser beam.

- Emergency Procedures: In the event of an accident or injury, it is important to have emergency procedures in place. This may include having a designated first aid kit, knowing how to contact emergency services, and having a plan for evacuating the work area if necessary.

- Maintenance: Regular maintenance of the laser cleaning equipment is essential to ensure its safe and effective operation. This includes checking for any signs of wear or damage, replacing any worn parts, and calibrating the equipment as needed.

- Compliance: It is important to ensure that all safety regulations and guidelines are followed when using laser cleaning equipment. This may include complying with OSHA regulations, following manufacturer recommendations, and obtaining any necessary permits or certifications.

By following these safety considerations, operators can minimize the risks associated with laser cleaning of metal surfaces and ensure a safe working environment for themselves and others.